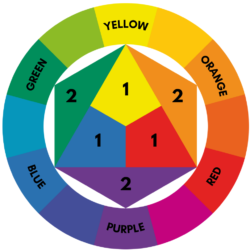

Natural Resins: A “Blank” Canvas

When it comes to color in plastics, the resin isn’t just the base—it’s the canvas. Every resin behaves differently in processing, interacts uniquely with pigments, and influences the final appearance of the part. That’s why understanding the natural characteristics of your resin is just as important as the color target itself. What is a "Natural" Resin? A “natural” resin is simply the base polymer in its uncolored, unfilled [...]