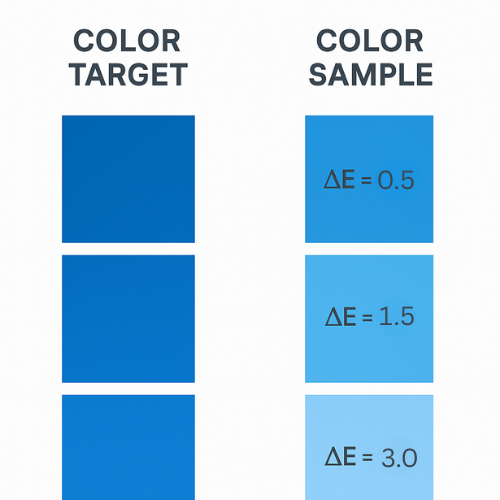

In color compounding, precision directly impacts product quality and customer trust. The X-RITE spectrometer is a proven tool that ensures measurable accuracy and repeatability in color matching processes. Using advanced spectral measurement technology, X-RITE captures color data with remarkable precision, allowing compounders to replicate colors reliably. Whether working with complex custom colors or industry standards, this device helps eliminate guesswork and costly rejections due to color deviations. This spectrometer offers quantifiable precision, with accuracy typically within 0.01 to 0.05 ΔE (Delta E), significantly reducing color variance between batches. By precisely capturing spectral data, compounders can consistently reproduce exact color specifications, minimizing batch rejections and reducing waste.